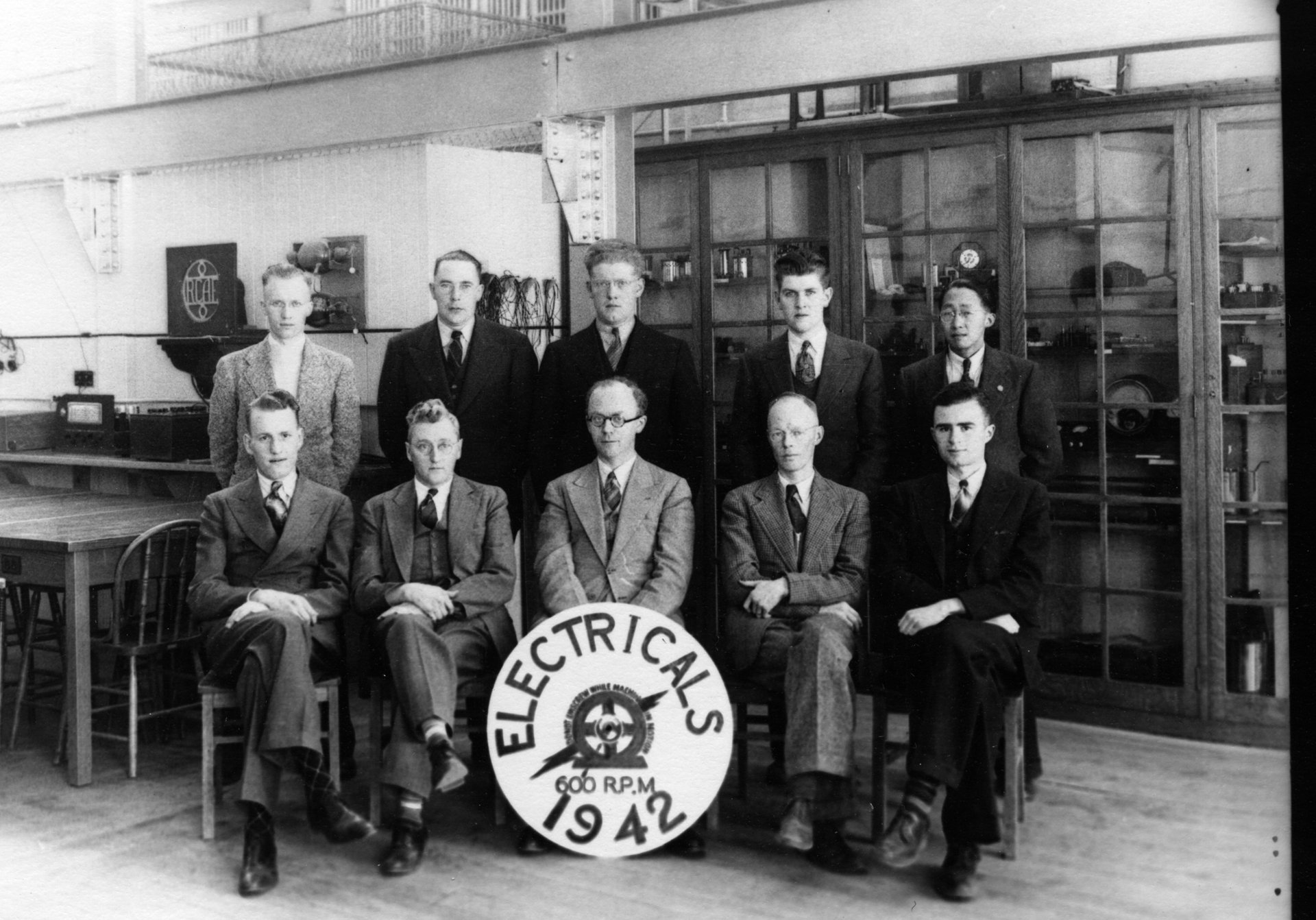

Photo courtesy of University of Calgary

Researchers Collaborate on COVID-19 Response

In early May, as the pandemic snaked through the province and cases climbed, researchers from the University of Calgary—part of a Facebook group called Shield Makers YYC—developed a plan to create a face shield the local community can use.

The group of professional engineers, designers, creators, and distributors collaborated on a dozen prototypes, connecting with Alberta Health Services (AHS) to test the shields and estimate production numbers. The Maker Multiplex in the university’s engineering faculty was instrumental in the creation of the prototypes. Volunteers from Calgary’s Fuse33 Makerspace did most of the labour in building the final products.

The face shields are similar in style and size to the ones already used by AHS, and they can be produced quickly and at high volumes in the event of a shortage. Orpyx Medical Technologies has signed on as the manufacturer, and engineering consultant Exergy Solutions has been providing support and can assist with manufacturing if needed.

Health officials have ordered 12,000.

Another Alberta success story

A group at the University of Alberta also has some skin in the game, making 3D-printed face shields for health-care workers.

The Elko Engineering Garage, a makerspace at the University of Alberta, joined up with the Alberta 3D PPE team—consisting of professional engineers, clinicians, and designers— and AHS to print and donate more than 2,000 reusable face-shield kits to front-line workers.

The team isn’t trying to recreate the wheel when it comes to a shield design that already works. Rather, it’s proactively managing a potential shortage. Any shields not used by AHS will be sent to Alberta nursing homes.

The effort was a successful demonstration of community collaboration. Elko donated 313 face shield frames made in 3.5 weeks on 19 printers to the project. The University of Alberta Library also stepped in, loaning 10 3D printers and a laser cutter to the team and donating about 50 spools of filament. And local manufacturing company Karma Machining & Manufacturing sanitized, packaged, and shipped the kits. Volunteers from the community and students from the university rounded out the project’s roster of participants.

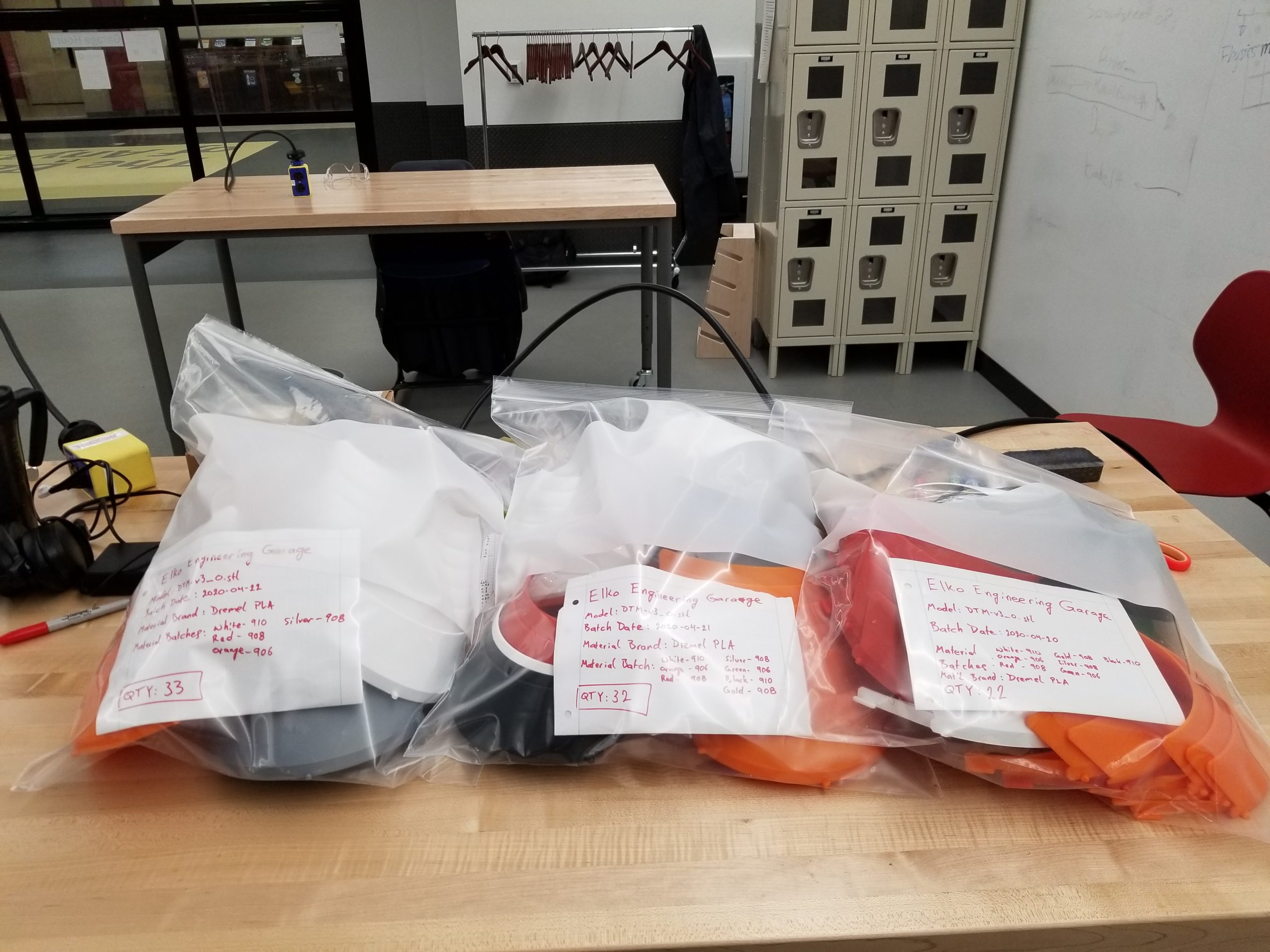

When the pandemic hit, a team at the Elko Engineering Garage got to work printing face shields and donating them to front-line workers.

Photo courtesy of Aaron Zidichouski, Engineering at Alberta

The face shields created at the University of Alberta—sanitized, packaged, and ready for action.

Photo courtesy of Aaron Zidichouski, Engineering at Alberta