Provincial Archives P2988

Getting a Jump on Sour Gas Processing

The people who worked there called it Jumping Pound University.

They were talking about Shell’s Jumping Pound gas plant, near Cochrane.

In 1952 it became the first plant in the world to remove toxic hydrogen sulphide from natural gas and convert it to sulphur.

Prior to this, hydrogen sulphide—commonly known as sour gas—was considered a waste by-product in the process of getting the good stuff. It was flared into the atmosphere for decades.

Then came an increased market demand for sulphur, along with government pressure to reduce flaring. That spurred industry, with a lot of input from Alberta engineers and geoscientists, to come up with solutions.

At Jumping Pound, liquid sulphur was hardened instead of vented, then sold to make everything from fertilizer and newsprint to matches and rayon.

The revolutionary new plant was a sour gas laboratory of sorts for the 30 engineers and geoscientists who operated and maintained it. Many of the performance and safety innovations developed there became industry standards.

“We learned a lot in Jumping Pound because there wasn’t experience with sour gas,” Bill Fisher, P.Eng., a mechanical engineer, recalled in a 2003 interview for the Petroleum Industry Oral History Project. He arrived at Jumping Pound shortly after the plant opened.

Designed in California, the plant wasn’t built for Alberta’s harsh winter weather. Early challenges included dealing with frozen pipes, hoses, and boilers.

“So you experimented with things, you tried different materials,” Fisher said, “and you made things work. It was interesting and challenging for an engineer because there was no end to what you could do if you put your mind to it.”

The plant is still operating—although it’s undergone several expansions and modernizations over the years to increase capacity and make it more efficient. These include the addition of a high-tech control system in 1981, allowing operators to run the plant from a single command room.

Did You Know?

Canada’s first plant to scrub poisonous hydrogen sulphide from sour natural gas was built in Turner Valley in 1924, after a major deposit was discovered there by Imperial Oil. Designed by chemical engineer Samuel Coultis, the Turner Valley plant, like Jumping Pound, was revolutionary.

Scrubbing made the gas safe for piping to Calgary.

Unwanted hydrogen sulphide was vented from the Turner Valley plant until 1952, when a sulphur extraction unit was added. Start-up was just a month after Jumping Pound’s.

Coultis managed the plant until 1939 and pioneered many technological advancements there.

Shut down in 1985, the Turner Valley plant is now a Provincial Historic Resource and a National Historic Site.

Dignitaries and citizens gather in June 1952 to celebrate the opening of the Jumping Pound sour gas plant near Cochrane.

Provincial Archives P1621

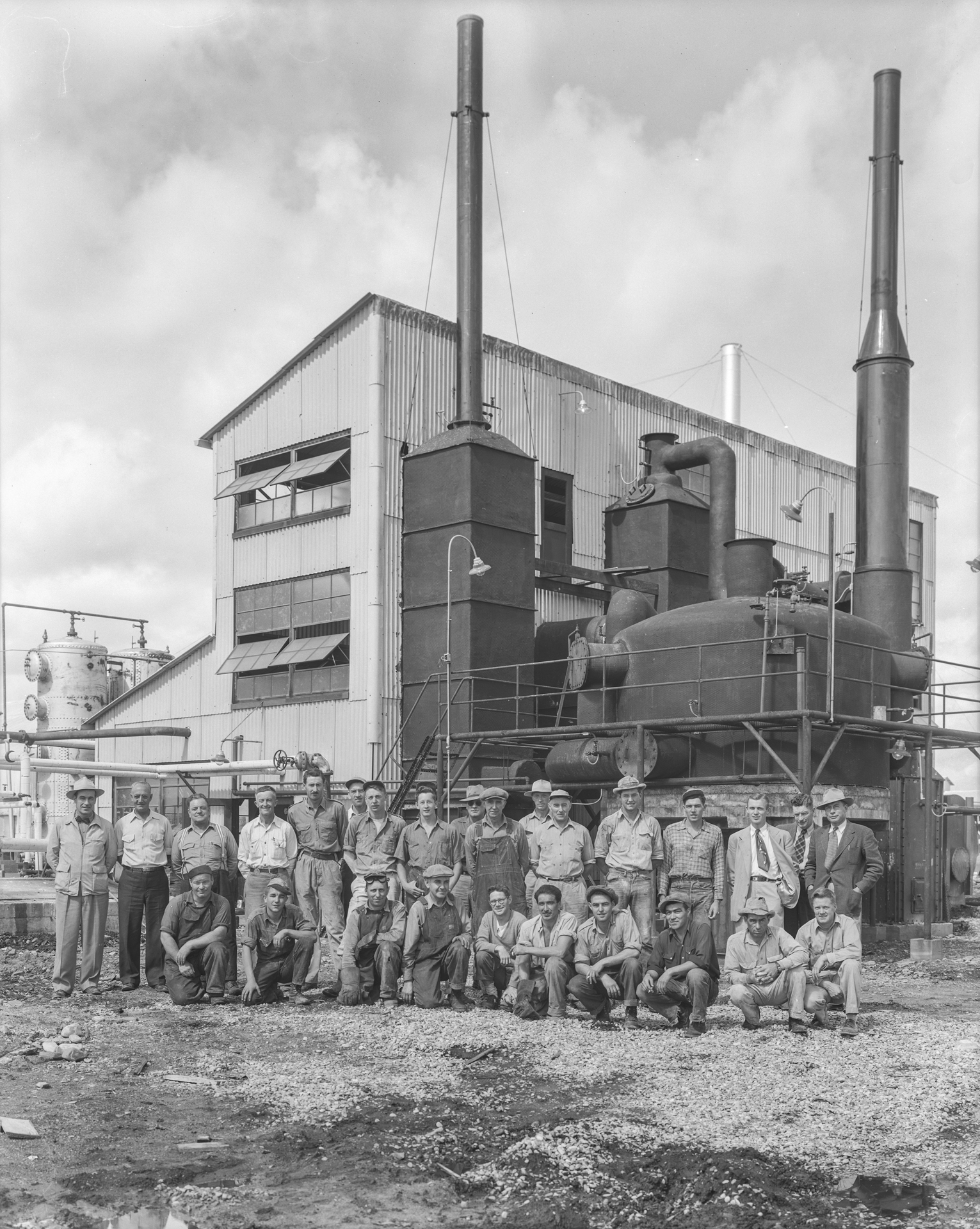

Staff at the Turner Valley gas plant in 1952, when a sulphur extraction unit was added.

Provincial Archives P2988

The evolution of the Turner Valley gas plant from its construction in 1924 to its designation as a provincial and national historic site.