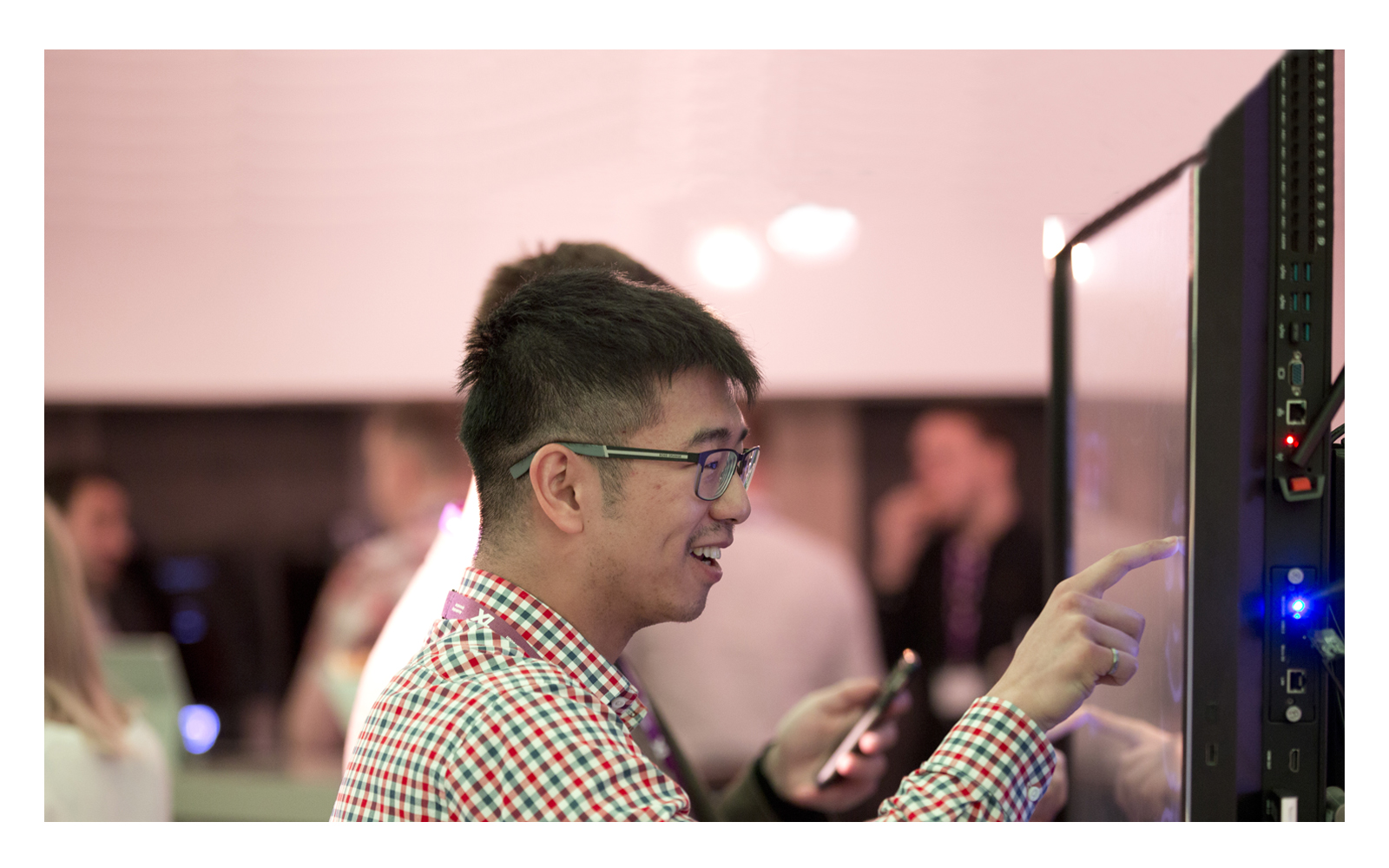

Photo courtesy of Oil and Gas Technology Centre

A Pollution Solution: Turning CO2 Green

Through ingenuity and engineering, carbon emissions in Alberta are being transformed from a wasted resource into useful products. But can it be done at a commercial scale?

That’s the question engineer-in-training Peter Zhou is hoping to answer through his work at CUT—Carbon Upcycling Technologies—a Calgary-based clean-technology company and one of the top 10 finalists for the $20 million US Carbon XPRIZE.

CUT has been busy developing innovative technology that converts CO2 into solid nanoparticles—fine, organic materials that can be added to plastics, protective coatings, concrete, asphalt, batteries, and other consumer products to make them stronger and more efficient.

“It allows us to take the pollution of today and transform it into the materials of tomorrow,” explains Zhou, a special project manager with CUT. “It will deliver value for years to come.”

But converting carbon into green goods isn’t the only benefit of the technology—it’s also helping reduce the amount of emissions entering the atmosphere. CUT’s technology sequesters between 50 to 150 kilograms of CO2 per tonne of product.

For the past couple of years, CUT has been refining its approach at the Alberta Carbon Conversion Technology Centre, a CO2 capture–and–conversion demonstration site owned and operated by InnoTech Alberta.

The centre, located in southeast Calgary, is next to the Shepard Energy Centre, which supplies the carbon emissions used by CUT for its testing.

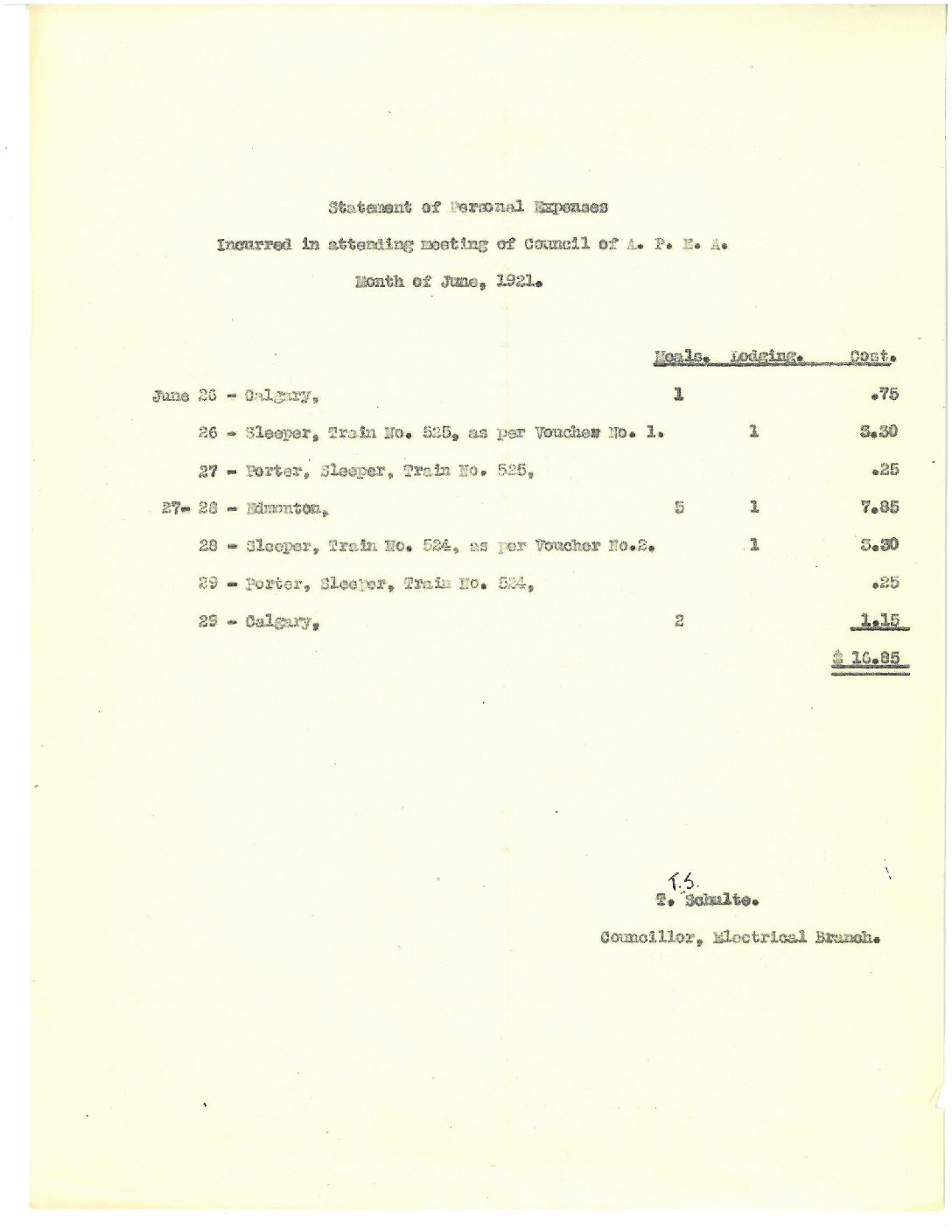

Carbon Upcycling Technologie’s one metric tonne per day reactor skid-mounted at the Alberta Carbon Conversion Technology Centre.

Photo courtesy of Carbon Upcycling Technologies

Four other Carbon XPRIZE finalists are also working out of the centre on CO2 conversion projects. The winner will be announced in the fall of 2020.

“The competition is about demonstrating scale, which is critical as we try to address the challenge of global warming,” remarks Zhou.

“We’re solving a business problem for someone and, at the same time, helping them offset their carbon intensity. It’s about solving the problem of climate change—which I call planet change—which systemically affects the Earth, not just in terms of rising global temperatures. It also affects food, water, and shelter.”

Zhou, 27, who was born in Harbin, in northeastern China and grew up in Calgary, earned a chemical engineering degree from the University of Calgary in 2016 and a master’s of chemical engineering from the University of Toronto in 2017.

In addition to his work with CUT, he’s also the co-founder of Green Mesa, a business aiding oil and gas companies to make more informed, sustainable decisions using cloud-based analytics to optimize their facilities.

While his career is only beginning, he’s eager to use his engineering skills and training to accelerate positive change for the future.

“I think there is a real opportunity to showcase to the world what remarkable things engineers can do,” adds Zhou. “It’s about working together to make the Earth a sustainable place for everyone.”

A CUT above

In 2017, after only two-and-a-half years in business, CUT became the youngest carbon–utilization company to generate commercial revenue. Already, CUT’s carbon–captured additives are being used in a variety of applications, including:

- civil infrastructure, such as corrosion–protection coatings used in manholes, septic systems, pump stations, sewer and wastewater systems, and grease–interceptor linings in restaurant kitchens

- consumer products, such as watches, pens, coasters, and yoga mats