Photo courtesy of Suncor Energy Inc.

Engineering Ingenuity Unlocks Alberta’s Oil Sands

When it opened in 1978, Syncrude’s massive oil sands mining operation at Mildred Lake was the largest single project in the province’s history. Not only that, it was a testament to the skills and ingenuity of the professional engineers who helped build it.

Financed by government and industry, the megaproject took five years to complete at a cost of $2.3 billion. An estimated 3.5 million hours went into its design, engineering, procurement, and project management. Trucks hauled more than 450,000 tonnes of construction material to Fort McMurray, including 500 kilometres of pipe for the refinery.

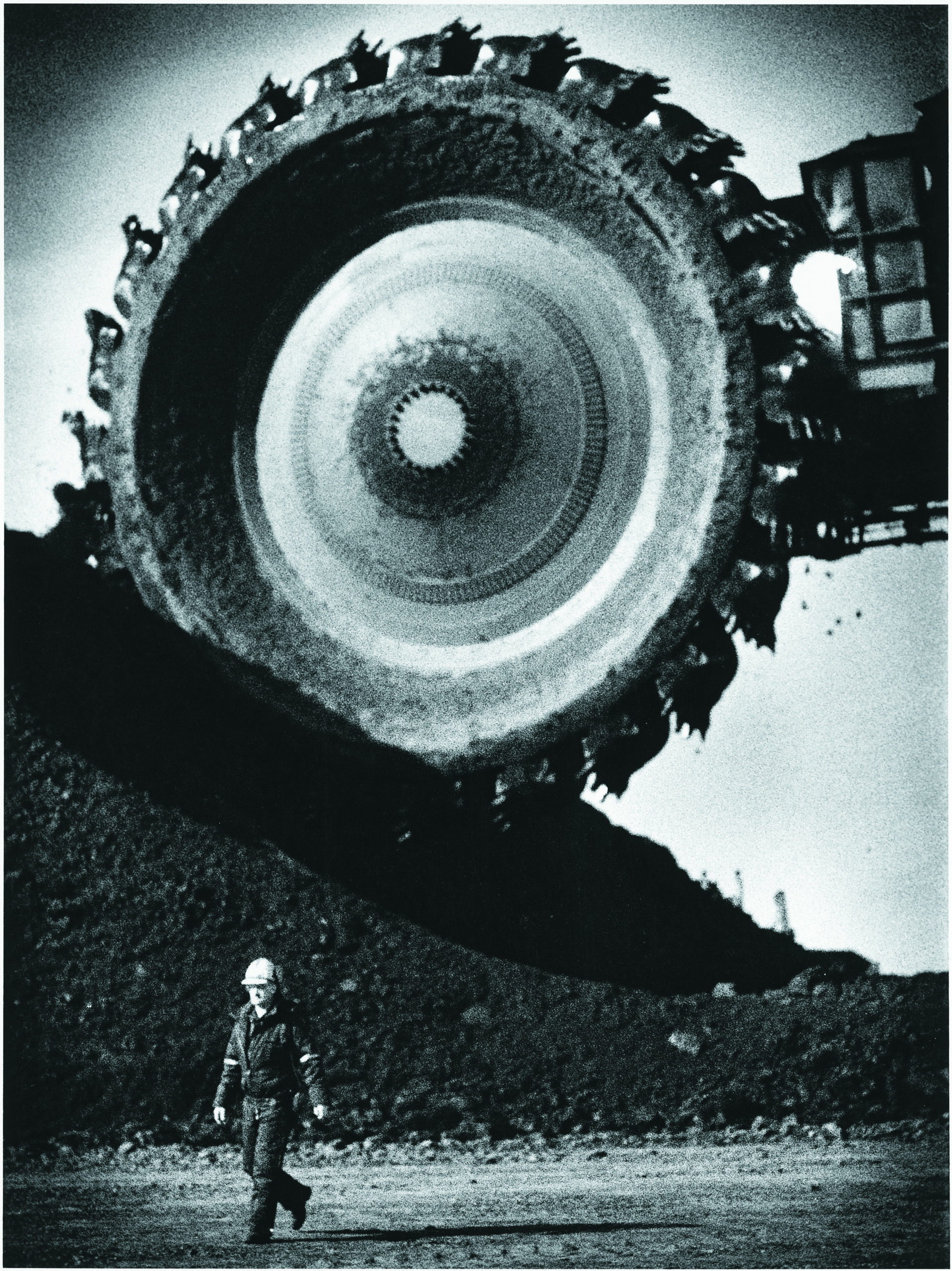

Once operational, the project’s giant drag lines dug up the earth—a mix of sand and bitumen—and 10-storey-tall bucketwheels scooped it onto conveyors to get it to the refinery. There, this challenging feedstock was transformed into synthetic crude oil.

Initial production was about 125,000 barrels per day. An electric generation station powered the complex, and the latest in engineering innovations allowed refining in extreme temperatures, ranging from –50 to +40 C.

It was Alberta’s largest oil sands commercial operation—but not its first.

That milestone was achieved in 1967 with the opening of the Great Canadian Oil Sands plant, north of Fort McMurray. Described then as a “daring venture into an unknown field,” the project of Sun Oil (now Suncor), overcame many early production hurdles. This firmly established the plant as a pioneer in oil sands extraction and upgrading technology, and laid the groundwork for all projects to come.

The Suncor and Syncrude developments were the culmination of years of engineering research embarked upon decades earlier.

Working for the fledgling Alberta Research Council in the 1920s, engineers Karl Clark, PhD, and Sidney Blair were leaders in the development of hot water extraction, the process used to unlock bitumen from sand. They were awarded a Canadian patent for the technology in 1928.

Initial research focused on using bitumen for paving. That quickly changed after Dr. Clark reported that bitumen could potentially be used for motor fuel “when the demand for crude oil becomes more keen and its price commences to rise.”

Progress was slow, but engineers and entrepreneurs continued to perfect hot–water extraction technology through the 1930s and 1940s. In 1950, Blair was hired by the provincial government to study the economic and engineering feasibility of commercial oil sands development. His landmark report suggested that mining operations could indeed be profitable, setting the stage for future growth.

Another driving force behind oil sands development was Frank Spragins, P.Eng., who became Syncrude’s first president when the company was founded in 1964. Spragins was quick to establish Syncrude’s research and development department—a team of professional geologists, engineers, and scientists who worked to advance hot–water separation technology—and he led the push for the Mildred Lake development.

A look back at development of the Great Canadian Oil Sands project in the 1960s

SUSTAINABLITY FOR THE FUTURE

More than 40 years later, APEGA engineering and geoscience professionals in industry and academia continue to redefine the limits of oil sands science and technology.

They’ve developed new innovations that have helped oil sands companies improve productivity, reduce water consumption, use less energy, and decrease carbon emissions. They’re also experts who create and implement long-range reclamation plans, restoring the landscape after oil sands mining is complete.

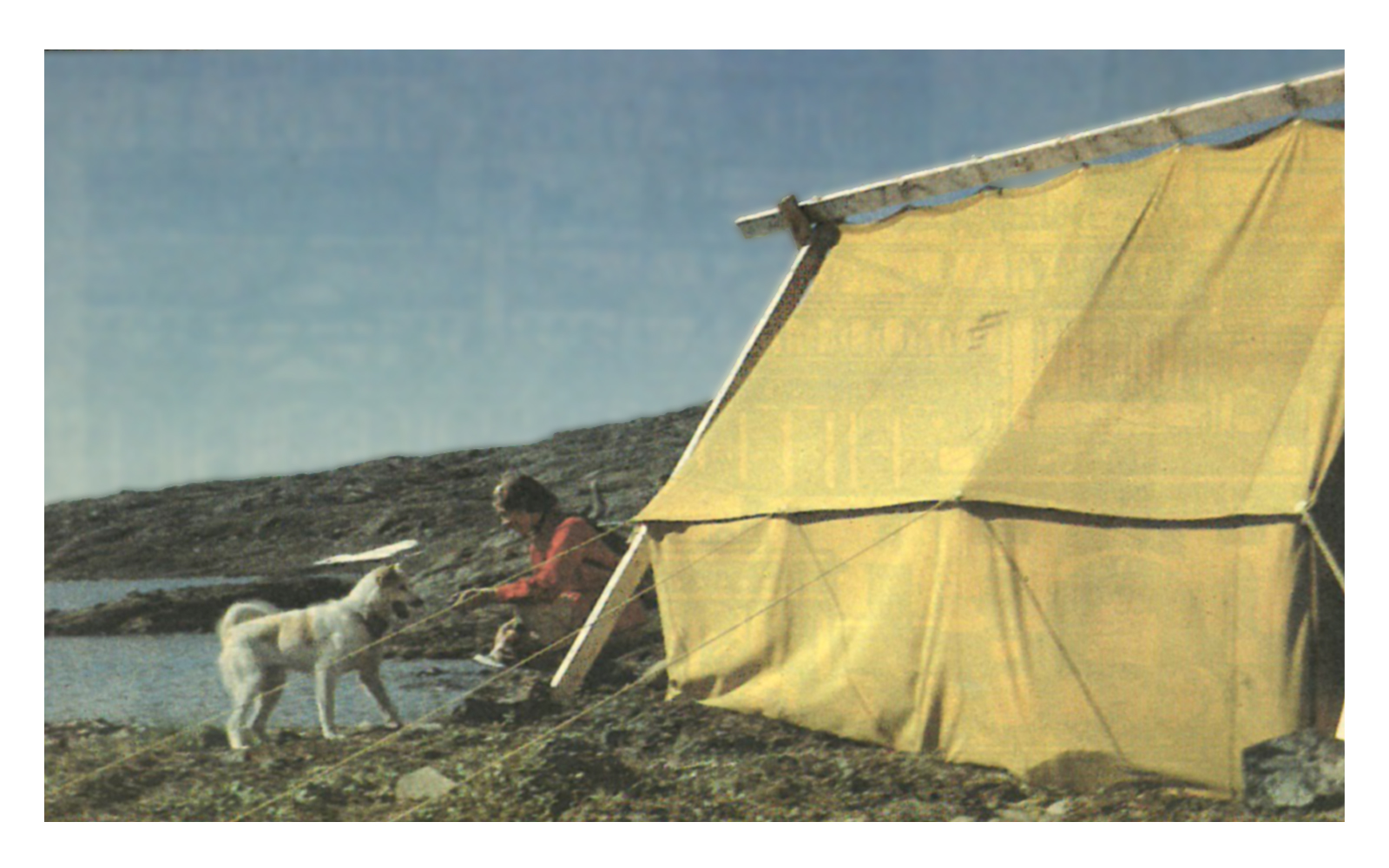

Suncor’s Melinda Mamer, P.Eng., explains tailings pond reclamation

Did You Know?

Alberta’s oil sands constitute the third–largest proven oil reserves in the world, after first-ranked Venezuela and Saudi Arabia. In addition to the Athabasca oil sands deposits around Fort McMurray, other fields can be found in the Cold Lake and Peace River regions.

In October 2019, Syncrude produced its three-billionth barrel of crude oil at the Mildred Lake complex, a milestone not reached by any other single source of oil production in Canadian history.

Frank Spragins, P.Eng., served as APEGA’s President in 1975 while construction of the Syncrude oil sands plant was in full swing. The Frank Spragins Technical Award, one of the Summit Awards, presented by APEGA, recognizes professional engineers and professional geoscientists who demonstrate integrity, technical expertise, and outstanding accomplishments in engineering or geoscience.

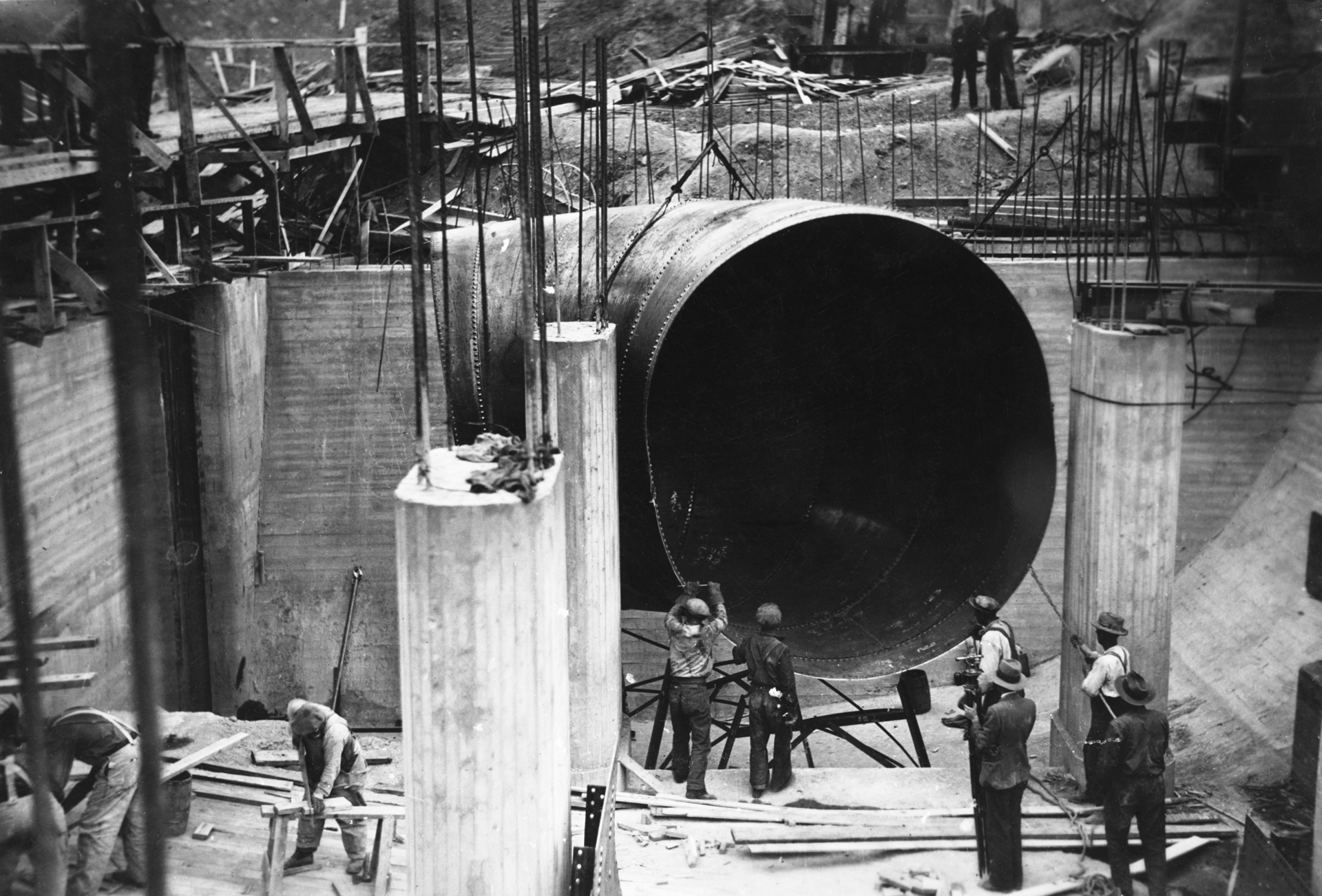

Glenbow Archives NA-5059-1os

Chemist and engineer Dr. Karl Clark, PhD, P.Eng. conducts research into oil sands extraction at the University of Alberta in 1929.

Glenbow Archives ND-3-4596a-os

An unnamed chemical engineer at Bitumount in 1951. The experimental oil sands separation plant near Fort McMurray had various owners between 1925 and 1958. In the late 1940s, Dr. Clark worked there, perfecting the hot-water extraction process.

Glenbow Archives PA-1599-451-4

Peter Read, P.Eng., talks about the technology evolution at Syncrude on the 50th anniversary of the company’s milestone oil sands development at Mildred Lake

Syncrude engineers Warren Zubot, P.Eng., and Gail Buchanan, P.Eng., are investigating ways to speed up the reclamation of oil sands tailings.

Photo courtesy of Syncrude Canada Ltd.

In 2010, Suncor was the first oil sands company in Alberta to convert a tailings pond to a stable surface that’s solid enough to support plants and wildlife. Wapisiw Lookout, which stored oil sands tailings between 1967 and 1997, is now a 220-hectare watershed.

Photo courtesy of Suncor Energy Inc.

Upgrading transforms bitumen into a high-quality synthetic crude oil that’s light and sweet (low sulphur). Syncrude uses three fluid cokers and a hydrocracker to thermally crack long carbon molecule chains into hydrocarbon gases, naphtha, and gas oils.

Photo courtesy of Syncrude Canada Ltd.

For decades, bucketwheels were used at Syncrude for oil sands mining. The last one was retired in 2006, replaced by trucks and shovels.

Photo courtesy of Syncrude Canada Ltd.