Photo courtesy of Lantic

Sweet Story: Made-in-Alberta Sugar

Taber is famous for its sweet corn, but another southern Alberta crop is even sweeter.

Farmers in the region have been growing sugar beets in the region since 1902. There’s even a sugar beet refinery in Taber, in operation since 1950.

The Rogers plant is the last refiner of sugar beets in the country.

Other refineries in Canada make sugar using sugar cane, which can be less expensive than beets to get. But the Taber plant remains competitive, thanks in part to a major modernization in the 1990s. Engineering improvements helped boost production by 50 per cent, allowing the plant to process up to 6,000 tonnes of beets per day.

Engineers also had a major hand in a new wastewater treatment plant. Designed, constructed, and commissioned in less than a year, it reduced the refinery’s environmental impact.

Continual process improvements have increased sugar recovery from beets. Today, the plant produces about 1,000 tonnes of sugar per day during its peak season, from September to February.

Along with granulated sugar, the refinery makes icing sugar, molasses, those packets of sugar for your morning coffee, and other products.

Cattle get to enjoy the beets, too—livestock feed is a by-product of sugar beet refining.

To purchase Alberta-made Rogers sugar, look for a packaging stamp that starts with the number 22. This means the sugar is from Taber.

Taber’s sugar beet factory opened in 1950. Today it is the last operating sugar beet refinery in Canada. Production peaks from September to February, at about 1,000 tonnes of sugar per day. The plant uses steam turbines to produces its own electricity.

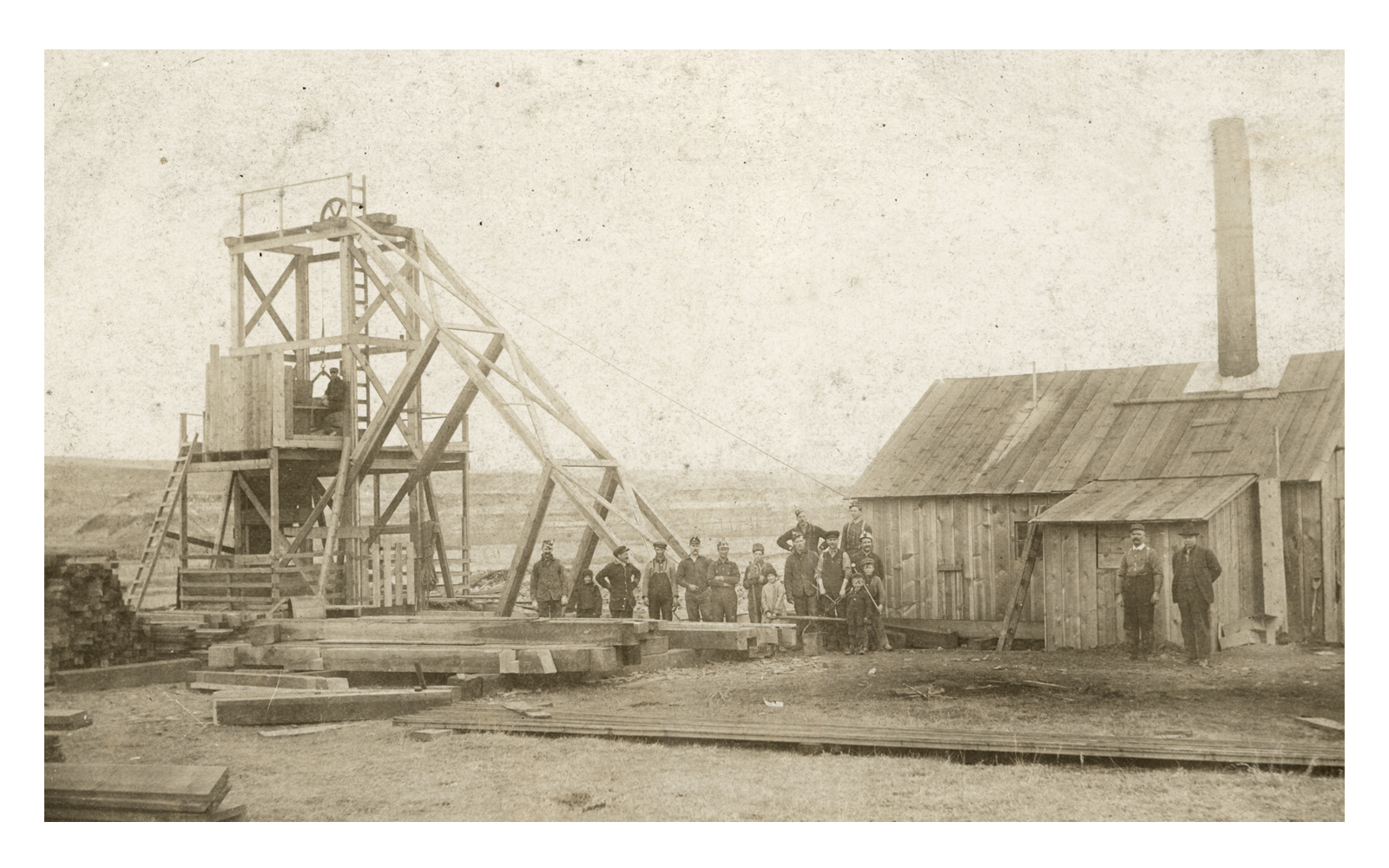

Glenbow Archives pa-3689-810

An aerial view of the Taber factory, circa 1950, which was originally operated by Canadian Sugar Factories.

Photo courtesy of Lantic

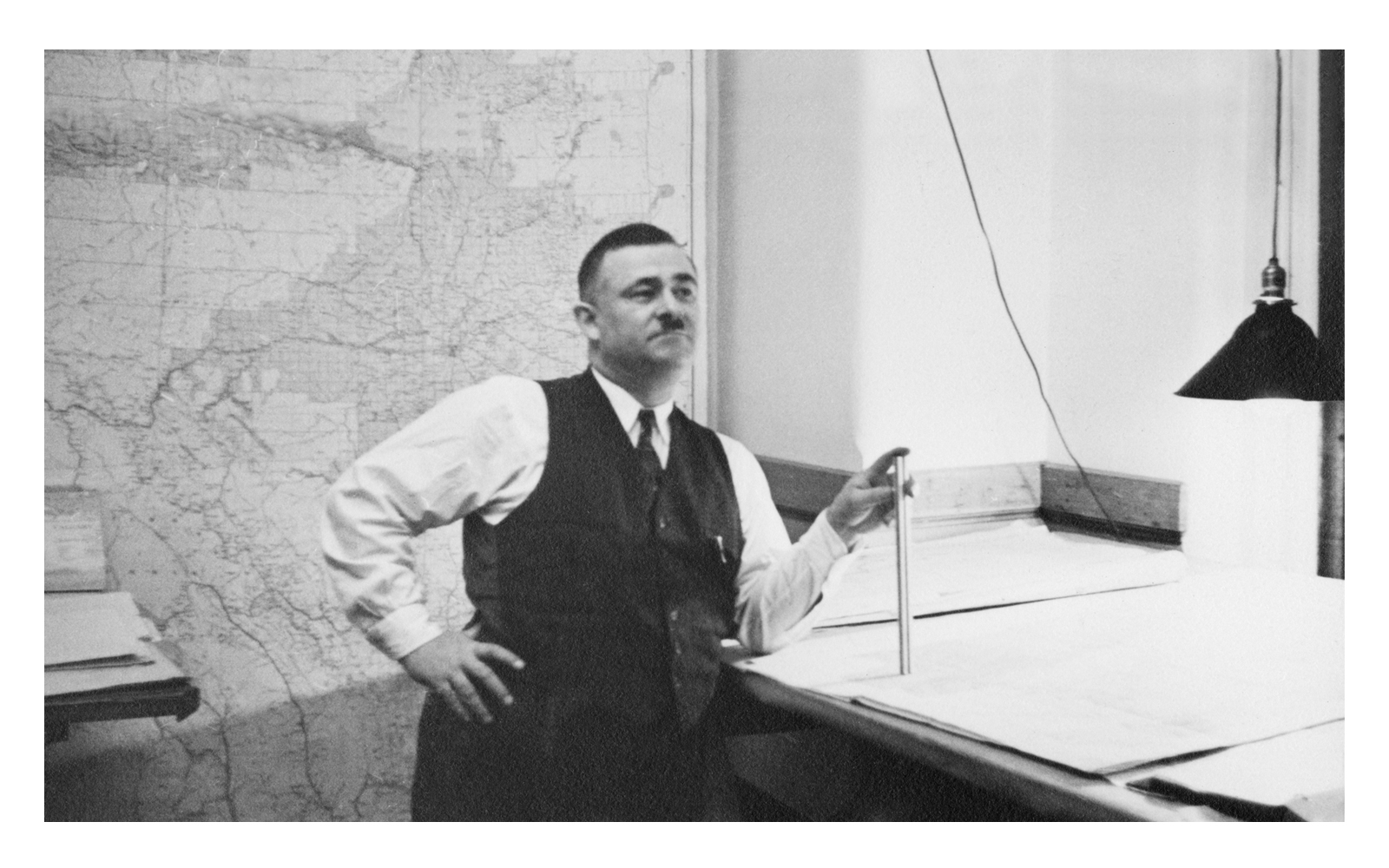

Inside a sugar beet refinery in Picture Butte, circa 1936.

Provincial Archives P3531

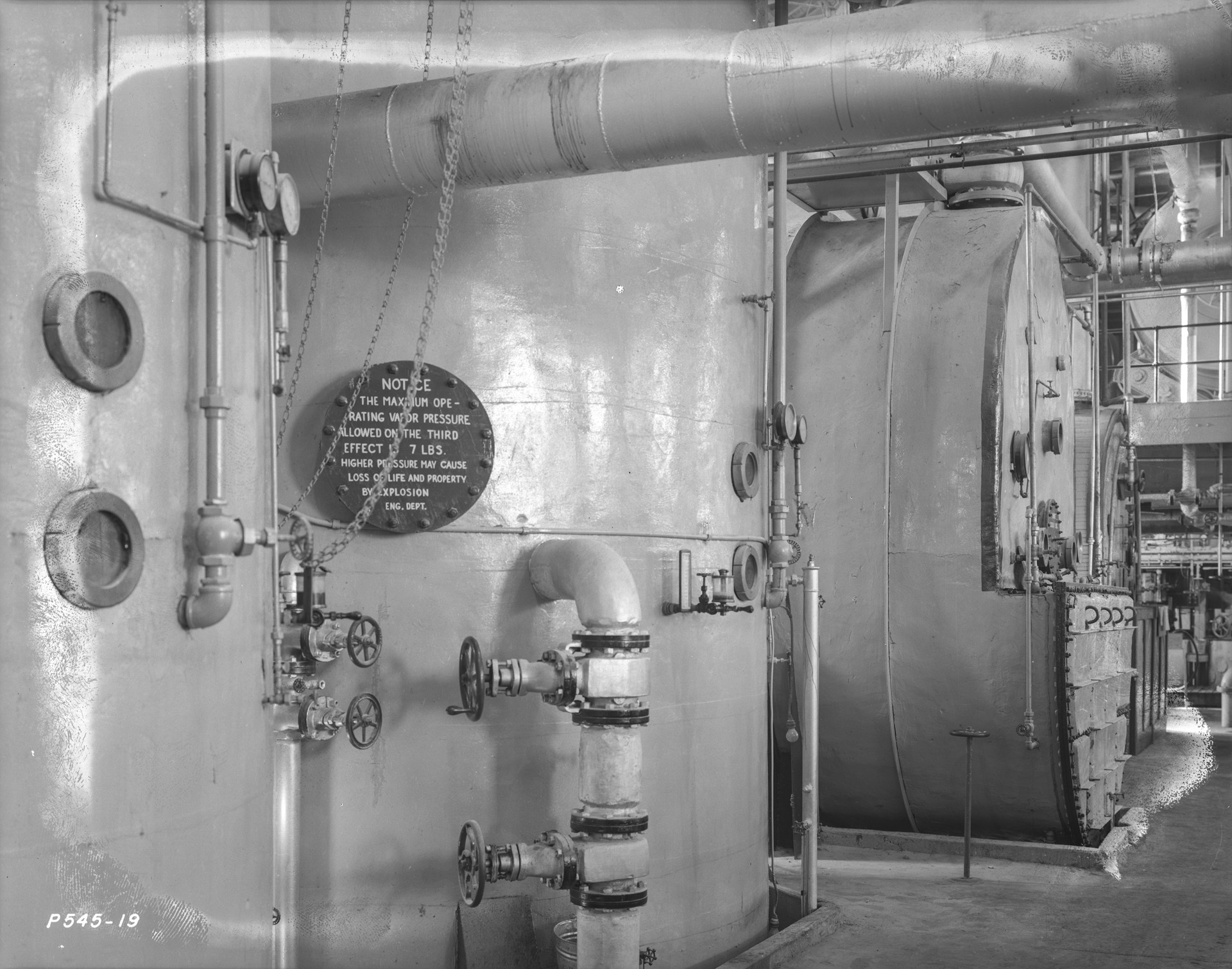

Signed by the plant’s engineering department, this safety notice in a sugar refinery in Picture Butte warns against using vapour pressure that’s too high. Doing so “may cause loss of life and property by explosion.”

Provincial Archives P3532

Alberta Sugar Beet Growers (shows history of sugar beet production and the inside of the plants)